A lot of people are surprised to hear there are tons of printing methods out there. Some methods are better suited for certain projects because of time, cost efficiency and/or quality. This post is to help you understand the different types of printing.

THE BASICS

Offset Printing

The Process:

Offset printing uses metal plates that transfer an image onto a rubber “blanket” and then the image is rolled onto a sheet of paper. Each color used requires a separate plate. The plates are then applied to the rollers that transfer the ink onto the paper.

Advantages of Using Offset Printing:

Offset printing is known for its efficiency which can be beneficial when printing large quantities. This type of printing also provides accurate color reproduction and pays great attention to detail. In the case of offset printing, the higher quantities you need to print, the more cost effective the price per unit will be.

Digital Printing

The Process:

Digital printing is the process of printing digital based images such as PDFs or publishing files that are then sent directly to the printing press. The images are then printed on paper, card stock, photo paper, and more.

Advantages of Using Digital Printing:

In contrast to offset printing, digital printing is favorable when smaller quantities are required. Digital printing is good for short run printing when you need up to 500 pieces printed. With digital printing, you have the capability of printing the exact amount you need, whenever you need it. This form of printing is an ideal platform for personalization such as names, addresses, numbers, and more.

SPECIALITY METHODS

Letterpress

The Process:

Letterpress printing is a form of printing where the image or text is on a raised surface. Then ink is applied to the raised surface and the paper is pressed directly against it to transfer the desired image or text.

Advantages of Using the Letterpress Technique:

Due to the visual impression letterpress printing leaves into the paper, it’s known for its elegance and handcrafted quality that is difficult to match using any other printing method. The different colors, impressions, and textures of the paper that are used influence the design production, leading to a uniquely crafted final product.

Foil Stamping

The Process:

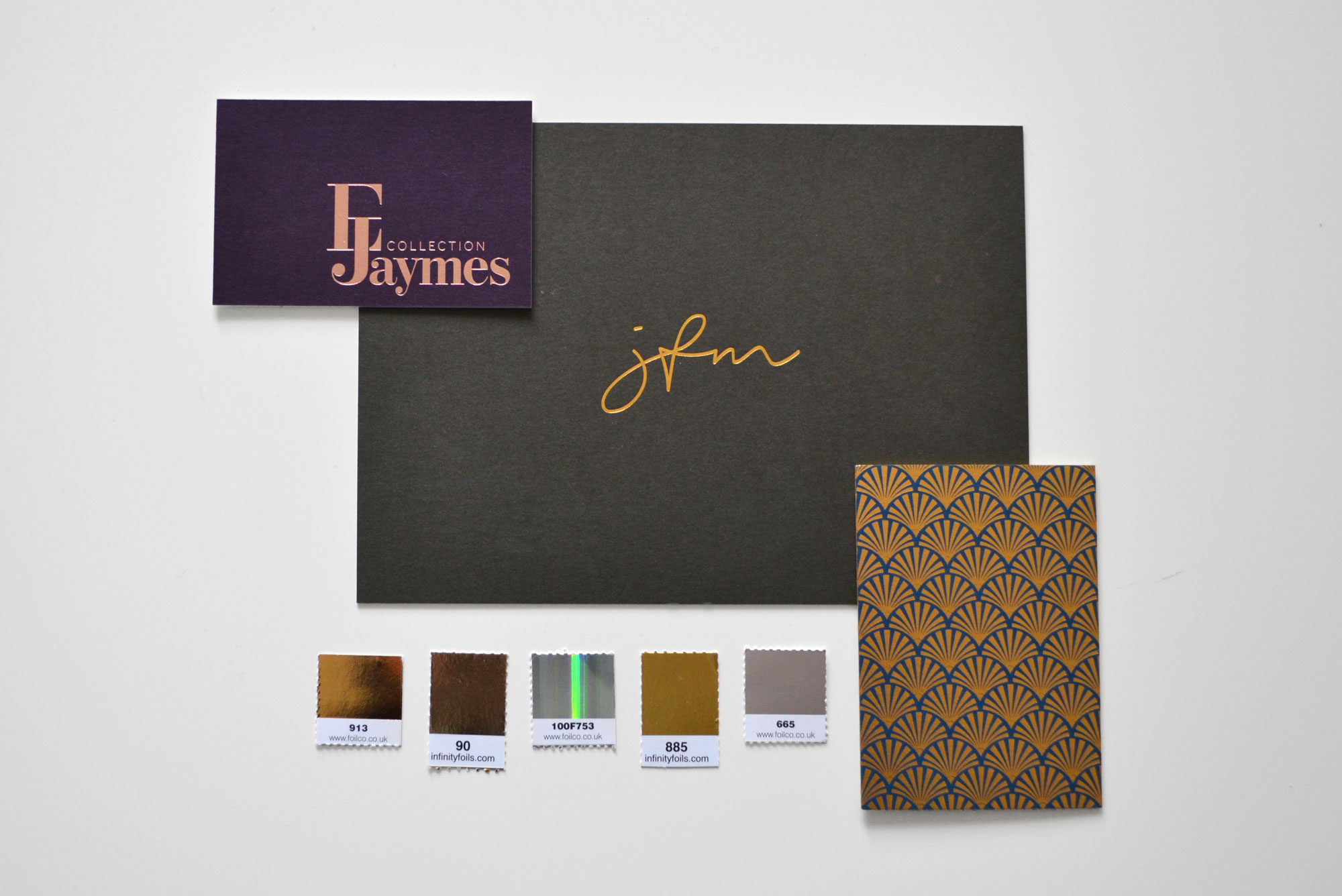

Foil stamping is a specialty printing process that utilizes heat, pressure, foil film, and metal dies. After a desired design is finalized, the metal dies are created in the correct shape for each color foil to be applied to the design. The dies are then heated and stamped to seal a layer of the foil to the paper.

Advantages of Using the Letterpress Technique:

One of the greatest advantages of using foil stamping is the ability to choose the colors, optical effects, and finishes of the foil roll. A wide assortment of foil rolls can be used such as metallic foil and solid foil colors that can have a glossy, matte, pearlescent, or patterned finish. Metallic or lighter color foil is great for designs that incorporate darker colored stock.

Duplex Printing

The Process:

Duplex printing is when two stocks are glued and mounted together, creating one thick and durable piece.

Advantages of Duplexing:

Duplex printing allows for stationery, business cards, and more to achieve a thickness of higher quality. The design can also be customized by using two different colored stocks on each side.

Image Sources

offset printer / digital printer